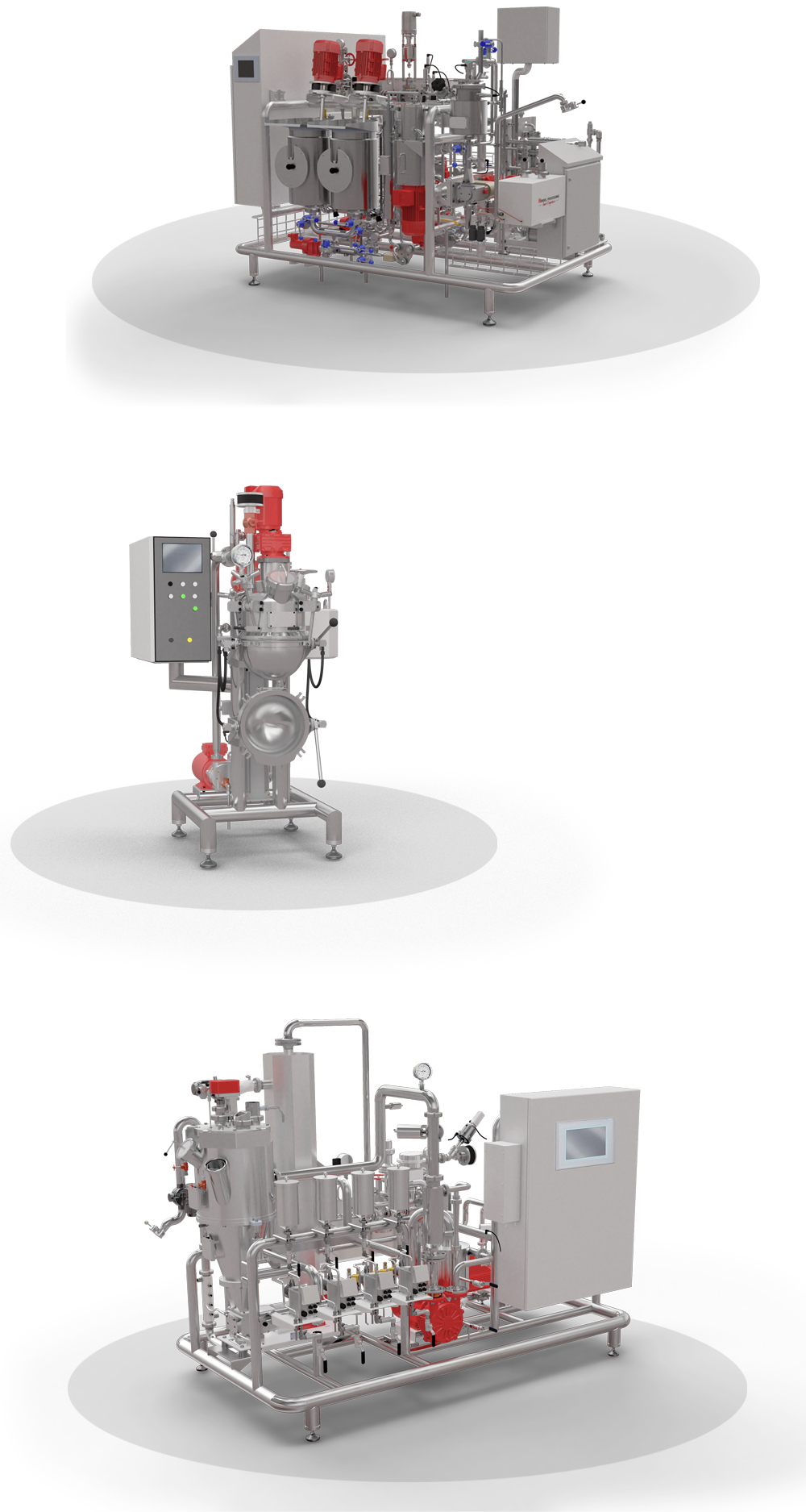

Develop new products and produce them in smallest quantities with the laboratory units Lab+, LSK 5 and ROTAMAT®

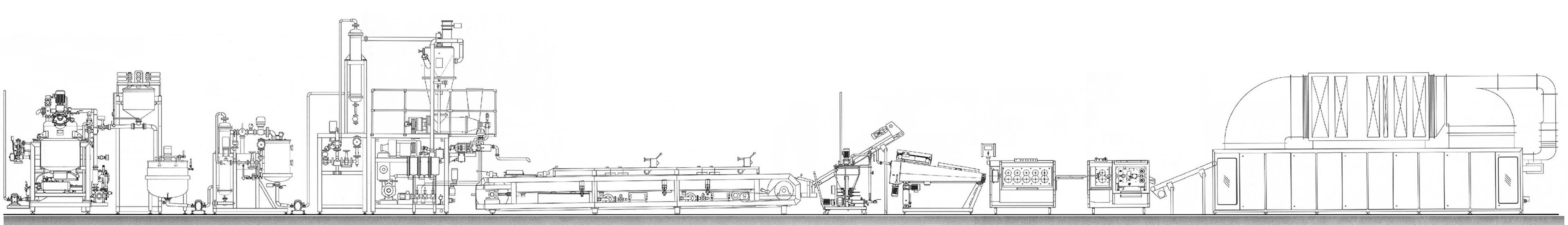

With our newly-developed unit line Lab+, we are offering a micro-unit that can continuously produce in a range from 8 to 16 kg/h.

Thanks to our innovative technology, a scale-up of the unit to larger throughputs is possible without any loss of quality.

This laboratory plant is particularly interesting for manufacturers of small quantities of high quality products, such as OTC products. Another application area for this small unit is the field of product development (R&D).

The integrated system has a raw material preparation station with a high-shear mixer for homogeneous mixing of raw materials. In addition to crystals, powders and liquids, all commercially available jellifying agents can be mixed too. Should the raw materials not be pre-weighed already, integrated weighing is possible. A frequency-controlled dosing pump delivers the pre-product to the JELLYSTAR® Lab+ or ROTAMAT® Lab+, (if dairy or protein-containing materials are being processed). A subsequent vacuuming lowers the temperature and water content of the mass before colours, flavours, acids or active ingredients are added in a continuous dosing station. Given that the quantities are very small, special pumps are employed, which can be optionally equipped with flow meters.

Especially interesting for newcomers or customers with little infrastructure at site:

- NPA option – the system does not need compressed air connection and therefore no compressor.

- NSS option – operated without steam which eliminates the need for steam installations or steam generators at installation site.

Given that direct access to the process parameters is of great importance in product development, a separate data login is an essential part of the installation concept of the new Lab+ line.

Other high-quality features of our unit are:

- simple and quick installation thanks to the plug & run concept,

- fast start-up and shutdown without product loss,

- excellent price/performance ratio,

- fast availability without long waiting times,

- high-quality components in the usual Hänsel industrial grade,

- perfectly suitable for feeding a laboratory depositor.

LSK5 - Cooking on an R&D scale.

The LSK5 laboratory cooker is universally applicable for the production of hard candies, fillings, caramel, toffees, chewy candies, fruit gummies, jellies and many other confectionery masses.

The configuration with a vacuum pump and scrapers in the cooking vessel offers a wide range of applications. Overpressure cooking in order to split up starch and for caramelisation is also possible. With batch sizes of approximately 5 - 7 kg, the cooker mainly finds its use in the R&D area.

LABORATORY-ROTAMAT 3609 - Cooking in the smallest format.

In combination with its vacuum system the continuous laboratory cooker ROTAMAT 3609 offers the cooking of candy masses under vacuum.

Combined with the CARAMASTER®, the vaporisation rate under overpressure can be increased, which leads to a higher grade of caramelisation.

Our ROTAMAT 3609 finds its use in development departments or big industrial plants as a bypass-cooker for milk recipes.