CARAMASTER®

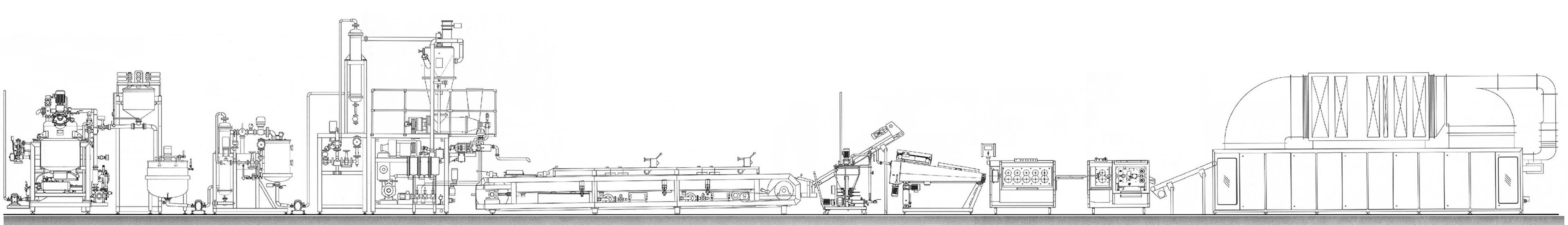

Caramelization with the CARAMASTER®

Our caramelization system consists of a double-jackeled, warm-water-heated container through which the mass is continuously passing. The caramelization of the respective mass depends on its residence time and temperature. Both of these parameters can be set separately in our CARAMASTER® caramelization system.

The fill level and residence time are reproducible at any time. The temperature is adjustable via a separate pressurized water circuit. The agitator is equipped with Teflon scrapers, which lead to a homogeneous caramelization without burning.

The dynamic spray nozzles arranged in the dome cover enable quick cleaning, which ensures a high availability of the system.

ROTAMAT®

Due to its special construction, the thin-layer rotor cooker ROTAMAT® 3610 / 3611 / 3612 is perfectly suitable for cooking sensitive confectionery masses that are prone to burning. These include milky hard candy masses, soft candy masses, toffees, milk fondant, caramel and fruit masses as well as other products which are being concentrated to a high TS.

Cooking under vacuum or overpressure is possible without any restrictions. In combination with the SUCOMA discharge system, confectionery masses can also be cooked under high vacuum.

While cooking with the ROTAMAT®, the masses are conveyed from bottom to top while ensuring a uniform residence time (first in - first out). That is a prerequisite for high and reproducible quality. The rotor forms a uniform film on the heating surface and whirls are generated by the scrapers, which ensures a very good heat transfer.